Contact

GET IN TOUCH

If you need some assistance, have a question or even some feedback, choose one of the contact methods below and let us know how we can help.

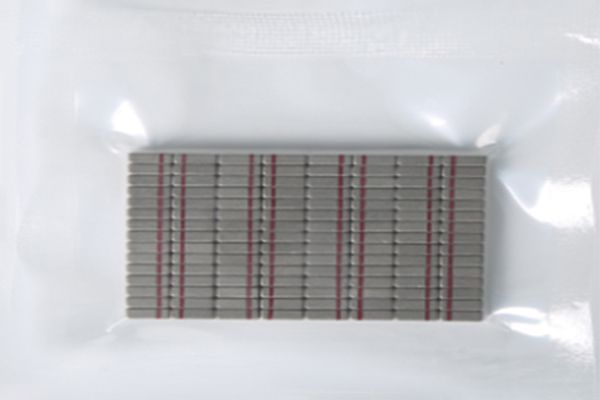

Ferrite magnets are characterized by their relatively low cost and good resistance to demagnetization. Ferrite magnets are made from a combination of iron oxide and other metal oxides. They have a moderate magnetic strength, making them suitable for a wide range of applications.

One of the advantages of ferrite magnets is their excellent corrosion resistance. They can withstand exposure to moisture and many chemicals without significant degradation. This makes them ideal for use in outdoor and industrial environments.

Ferrite magnets are available in various shapes and sizes, allowing for easy customization to meet specific design requirements. They are also easy to machine and can be cut, drilled, or ground to precise dimensions.

At Uni Magnetech, we ensure the quality of our ferrite magnets by adhering to strict manufacturing processes and quality control standards. Our ferrite magnets are reliable and perform consistently, providing value for our customers.

(max)

(max)

(max)

(min)

| Magnetic Properties of Ferrite Magnet | |||||||||

| Material | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy Product | Iso/Anisotropic | ||||

| Br | Hcb | Hcj | (BH)max | ||||||

| T | KGs | KA/m | KOe | KA/m | Koe | KJ/m3 | MGOe | ||

| Y10T = C1 | 0.200-0.235 | 2.00-2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.52 | 6.5-9.5 | 0.8-1.2 | Isotropic |

| Y20 | 0.320-0.380 | 3.20-3.80 | 135-190 | 1.70-2.38 | 140-195 | 1.76-2.45 | 18.0-22.0 | 2.3-2.8 | Anisotropic |

| Y22H | 0.310-0.360 | 3.10-3.60 | 220-250 | 2.77-3.14 | 280-320 | 3.52-4.02 | 20.0-24.0 | 2.5-3.0 | |

| Y23 | 0.320-0.370 | 3.20-3.70 | 170-190 | 2.14-2.38 | 190-230 | 2.39-2.89 | 20.0-25.5 | 2.5-3.2 | |

| Y25 | 0.360-0.400 | 3.60-4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 | |

| Y26H | 0.360-0.390 | 3.60-3.90 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 23.0-28.0 | 2.9-3.5 | |

| Y27H | 0.370-0.400 | 3.70-4.00 | 205-250 | 2.58-3.14 | 210-255 | 2.64-3.21 | 25.0-29.0 | 3.1-3.7 | |

| Y30 = C5 | 0.370-0.400 | 3.70-4.00 | 175-210 | 2.20-2.64 | 180-220 | 2.26-2.77 | 26.0-30.0 | 3.3-3.8 | |

| Y30BH = C8 | 0.380-0.390 | 3.80-3.90 | 223-235 | 2.80-2.95 | 231-245 | 2.90-3.08 | 27.0-30.0 | 3.4-3.7 | |

| Y30-1 | 0.380-0.400 | 3.80-4.00 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.65 | 27.0-32.0 | 3.4-4.0 | |

| Y30-2 | 0.385-0.415 | 3.95-4.15 | 275-300 | 3.46-3.77 | 310-335 | 3.90-4.21 | 28.5-32.5 | 3.5-4.0 | |

| Y32 | 0.400-0.420 | 4.00-4.20 | 160-190 | 2.01-2.38 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 | |

| Y33 | 0.410-0.430 | 4.10-4.30 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 31.5-35.0 | 4.0-4.4 | |

| Y35 = C11 | 0.400-0.410 | 4.00-4.10 | 175-195 | 2.20-2.45 | 180-200 | 2.26-2.51 | 30.0-32.0 | 3.8-4.0 | |

Ferrite magnets are commonly not coated mainly for the following reasons.

Firstly, ferrite magnets have good corrosion resistance by themselves. The main component of ferrite magnets is iron oxide, and their chemical properties are relatively stable. As they are already oxidized products, it is difficult for them to be oxidized further. Thus, they are not prone to rust or corrosion and do not require additional coatings for anti-corrosion protection.

Secondly, cost factor. The production process of ferrite magnets is relatively simple and low-cost. If coating treatment is carried out, it will increase additional production costs, including the cost of coating materials, equipment and energy consumption for coating processes. This may increase the overall cost of ferrite magnets and reduce their price competitiveness in the market.

Thirdly, less impact on magnetism. The magnetic force of ferrite magnets is relatively weak. Coatings may have a certain impact on their magnetism. For example, some metal coatings may have certain ferromagnetism, which will interfere with the magnetic field distribution of ferrite magnets and thus affect their magnetic properties. Without coating treatment, the original magnetic properties of ferrite magnets can be maintained to the greatest extent.

Fourthly, processing difficulty and process complexity. Ferrite magnets are usually relatively hard and brittle, and processing is difficult. Coating treatment requires additional process steps such as cleaning, pretreatment, and electroplating. This will increase the complexity and difficulty of the production process and may lead to a decrease in the product qualification rate.

If you need some assistance, have a question or even some feedback, choose one of the contact methods below and let us know how we can help.

+86-15355125251

No.7, Jiangqian Road, FengHua district, Ningbo 315157, China.